Products

Inspirational Glass Technology

Rigmah® Glass Coporation

Rigmah®-D

Rigmah®-DNano color-coated glass

Overview

- Unlike conventional paints, the special ink for electronic parts and construction is a mixture of transparent and reliable resin and organic/inorganic paint that is dispersed in nano size.

- There is no limitation in color, and the adhesive and durable film formed on the glass ensures high-quality printing.

Features

- Nano ink based on reliable hybrid resin

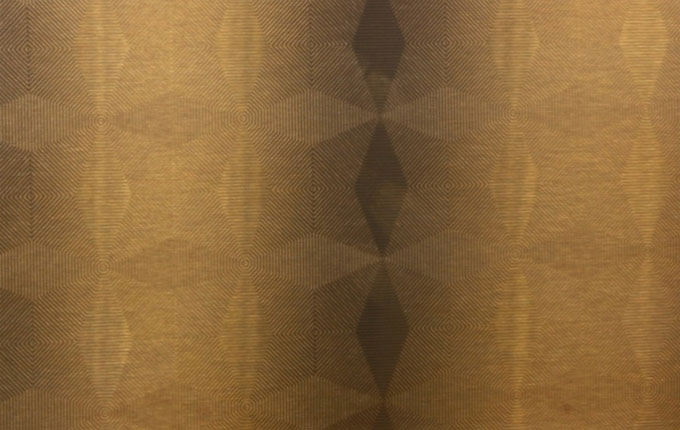

- Color ink that embodies the transparency of glass and the color and texture of metallic substance and film

- High-quality printing and coating with a wide range of colors and outstanding surface leveling

- Outstanding properties such as durability, chemical resistance, and adherence to glass, metal, and film

- Outstanding flexibility (bending and perforation) and reprintability

Usage

- All types of metals, glass, and films applied to home appliance products such as refrigerators, air conditioners, microwave ovens, and washing machines

- Pattern/color plates (metal and glass) for building interior and exterior

Coating Process

- Loading

- Cleaning

- ACoating(Screen Print)

- BCuring

- CCooling

- Inspection

- Lamination

- Un-Loading

-

ACoating(Screen Print)

- Max Size : 1,240 X 3,048mm

- Ink의 Viscosity : 3.0 ~ 20,000.0cp

- Coating Thickness. : 5~10um

-

BCuring

- Pre zone Temperature : 150 degrees

- Main Zone Temperature : 180 degrees

- Residence time : 300 ~ 550sec

-

CCooling

- Residence time : 60 ~ 180sec

Internal test report

| Test name | Test conditions | Test results |

|---|---|---|

| Cross-Cut | 3M Tape 1mm Cross Cut (#100/100) | OK |

| Water Heat test | Cross-cut test before and after 100°C X 1hr test | OK |

| Heat resistance test | 120±2°C, 24hr Negligence | OK |

| Thermal Shock test | -40°Cx 2hr, 80°Cx2hr, 10cycles | OK |

| Cosmetics resistance test | Nivea SPF45 80°C, 80% x 24hr | OK |

| T-bending | 2T T-bending Test | OK |

| Acid resistance test | 5% HCI x 72hr | OK |

| Detergent resistance test | 10-day negligence of synthetic detergent | OK |

| Water resistance test | 240-negligence at room temperature | OK |

| Salt mist resistance test | 5% NaCl Salt Spray, 72hr | OK |

| Humidity resistance test | 50°C 95% RH, 72hr | OK |

| Etanol Rubbing test | Et-OH(99.5%) 500g, 150times Rub | OK |

| Abrasion resistance test | Painting Surface 50 cycles with 275g | OK |

| Environmental test | No abnormalities on the film; There should be no swelling or peeling. | OK |

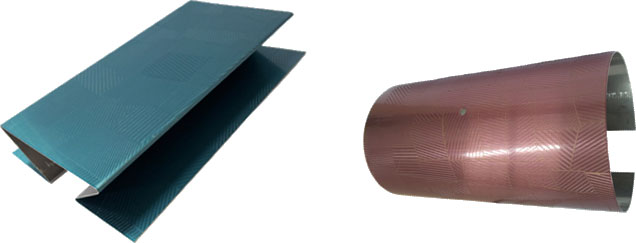

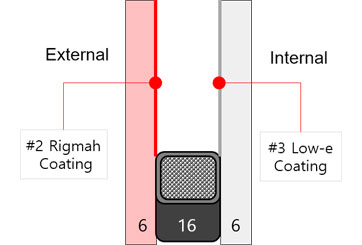

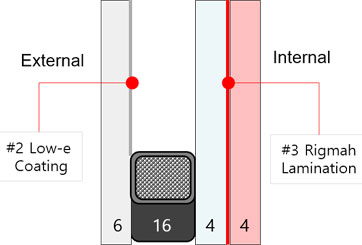

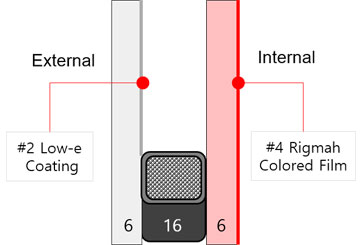

Proposal of 28 mm color dual layered glass for exterior

| Name | 28T color low-E dual layered glass (half reinforcement of one side) | 31T color lamented dual layered glass (half reinforcement of one side) | 28T color dual layered glass (half reinforcement of both sides) |

|---|---|---|---|

| Supplied price/Design price(KRW) | |||

| Specifications |

|

|

|

Cross-section details

|

|

|

|

| Visible light transmittance ratio (%) | 30~60(depending on the color) | 25~55(depending on the color) | 30~60(depending on the color) |

| Heat transmission coefficient(W/㎡K) | 1.55 | 1.54 | 1.55 |

| Shielding coefficient | 0.4~0.6(depending on the color) | 0.4~0.7(depending on the color) | 0.4~0.7(depending on the color) |

| Color |  |

(Customized color and adjustable transmittance ratio)

(Customized color and adjustable transmittance ratio)

|

|

| Customized color | X | O | X |

Application

- Home appliance

- Elevator

- Furniture

- Interior

Sample

Inquiry